|

||||

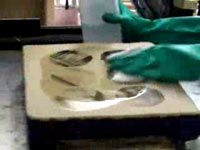

Prior to graining a stone ink from an old image is removed using solvents. |

Water and caborundum grit are applied to the stone. Coarse initially to remove old images and gradually finer. |

|||

|

Periodic checks are made to ensure that the surface of the stone is completely flat. |

|||

|

Once the stone is finely grained and scratch free it is cleaned and dried and is ready for an artist to draw on, or covered for storage. |

|||

Artists draw on the stones with greasy pencils & liquids. |

Once images are complete and dry they are dusted with rosin and talc. |

|||

Gum arabic and a few drops of acid are then applied to 'etch' the image. The stone is left for at least one hour. |

In the mean time we can set up the press with the correct size of scraper bar, which is used to appliy the pressure through. |

|||

The roller can also be prepped and ink mixed... |

...and rolled out. |

|||

The drawing materials are washed out using solvent. |

A greasy printing base of asphaltum is buffed in. This will aid the greasy ink stick to the stone where the image is. |

|||

The gum is removed from the stone with water and sponged evenly damp. |

The water on the non-image parts of the stone repel the greasy ink. |

|||

Once sufficiently rolled in ink the stone is dried and rosin & talc are dusted on again and a second (often stronger) etch is applied to help stabalise the image. |

The stone is left again for at least an hour. This gives us time to tear down some paper ready for printing. |

|||

Registration marks are added to the reverse of the paper, these correspond to marks that have been scratched into the stone. |

The image is washed out with solvent again, more asphaltum, gum removed with water and rolled up. A few newsprints will be printed prior to printing on good papers. |

|||

The paper is registered on the stone and run through the press. |

The impression is pulled from the stone. . |

|||

|

||||

| home / faq's / artists / services / news / contact | ||||